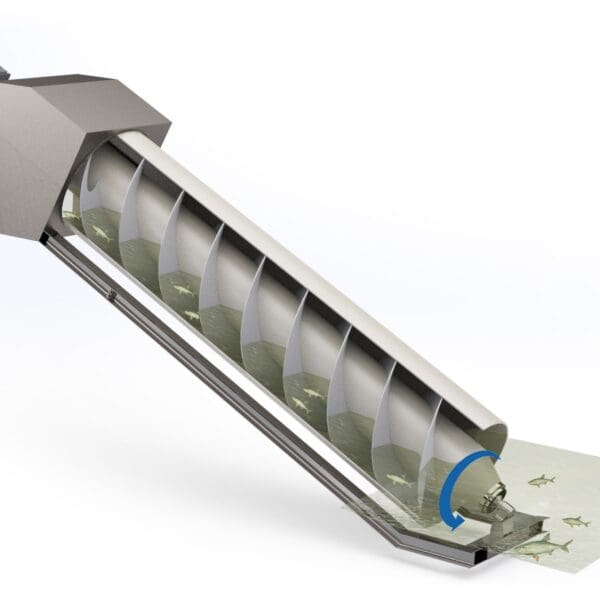

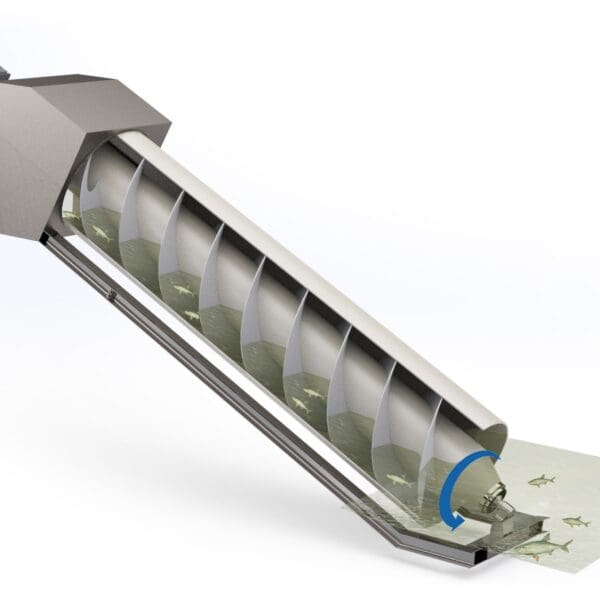

In conventional Archimedes screw pumps the first winding scoops water from the inlet and lifts it to the outlet with the subsequent windings. Migrating fish will pass through with the liquid and be transported to the discharge. Approximately 15% of fish will suffer an injury while passing through a conventional screw pump. Fish are damaged at the pump entrance by being struck by the first winding screw as it enters the water. Fish also get jammed between the rotating screw and the stationary trough in which the screw is placed.

FishFlow Innovations have modified the design of conventional Archimedes screw pumps and have created a design that does not inflict any damage to fish or eels passing through the pump. In the FishFlow screw pump the first blades in the pump entrance are not across the full width up to the tip of the screw, instead the width of the blades gradually decreases from the middle outwards during the last few windings. The second modification is manufacturing the housing and the screw in one piece so that the screw and enclosing pipe rotate together. These adaptations make damage to passing fish through hits of the first winding and damage from entrapment impossible. As a result we can claim that the FishFlow screw pump is the best 100% fish friendly pumping system for downstream migration of fish and Tuna species.

In conventional Archimedes screw pumps the first winding scoops water from the inlet and lifts it to the outlet with the subsequent windings. Migrating fish will pass through with the liquid and be transported to the discharge. Approximately 15% of fish will suffer an injury while passing through a conventional screw pump. Fish are damaged at the pump entrance by being struck by the first winding screw as it enters the water. Fish also get jammed between the rotating screw and the stationary trough in which the screw is placed.

FishFlow Innovations have modified the design of conventional Archimedes screw pumps and have created a design that does not inflict any damage to fish or eels passing through the pump. In the FishFlow screw pump the first blades in the pump entrance are not across the full width up to the tip of the screw, instead the width of the blades gradually decreases from the middle outwards during the last few windings. The second modification is manufacturing the housing and the screw in one piece so that the screw and enclosing pipe rotate together. These adaptations make damage to passing fish through hits of the first winding and damage from entrapment impossible. As a result we can claim that the FishFlow screw pump is the best 100% fish friendly pumping system for downstream migration of fish and Tuna species.